Magnetometry

Using a magnetometer on a drone enables us to scan the area and detect metals comparably faster than handheld devices, allows the creation of geo-referenced maps of the area, and removes the risk of injury to ground-based inspectors.

Magnetometry is the science of measuring the strength and direction of magnetic fields – providing a valuable tool in Archeology, Mineral Exploration, and Public Safety. Originally developed in the 1800’s by Carl Friedrich Gauss to formulate his law of magnetism, the application and use of Magnetometry has grown over its decades of use to become one of the most widely used geospatial survey techniques in the world.

In delivering these types of surveys, a Magnetometer is used to measure the strength and direction of magnetism in a specific area. Measuring magnetism allows for the detection and identification of any magnetic metals or materials, and allows an operator to deliver inspections that may include locating buried infrastructure, archaeological inspections, or any survey searching for metal objects weighing a few hundred grams or heavier underground.

While valuable, delivering these type of inspections can be time consuming and hazardous. The magnetometer is not an active sensor, so it only measures the magnetic field at the point where it is located. That means detecting objects (especially small ones) requires comprehensive coverage of an entire site – a process that can take days with traditional ground based surveys. In addition, delivering these surveys in undeveloped areas requires field staff to trek into potentially unsafe or unfamiliar locations, adding both time and risk to the project.

That is where the benefit of a drone-based system comes into play. The type and sensitivity of magnetometers does mean that magnetic inspections differ greatly from other aerial surveys. While typical drone-based surveys derive benefit from higher altitude capture with a high degree of accuracy and detail, drone-based magnetometry requires the platform fly as close to the surface as possible.

As a partner and trainer of SPH Engineering, which develops the UgCS line of equipment, we have the experience and technology to complete low altitude inspections safely and quickly. Our platforms use a SENSYS MagDrone magnetometer and true terrain-following systems with a precise laser altimeter, allowing our drones to fly as low as 1m AGL while rapidly collecting data on magnetic metals and materials.

How Can We Help?

Services

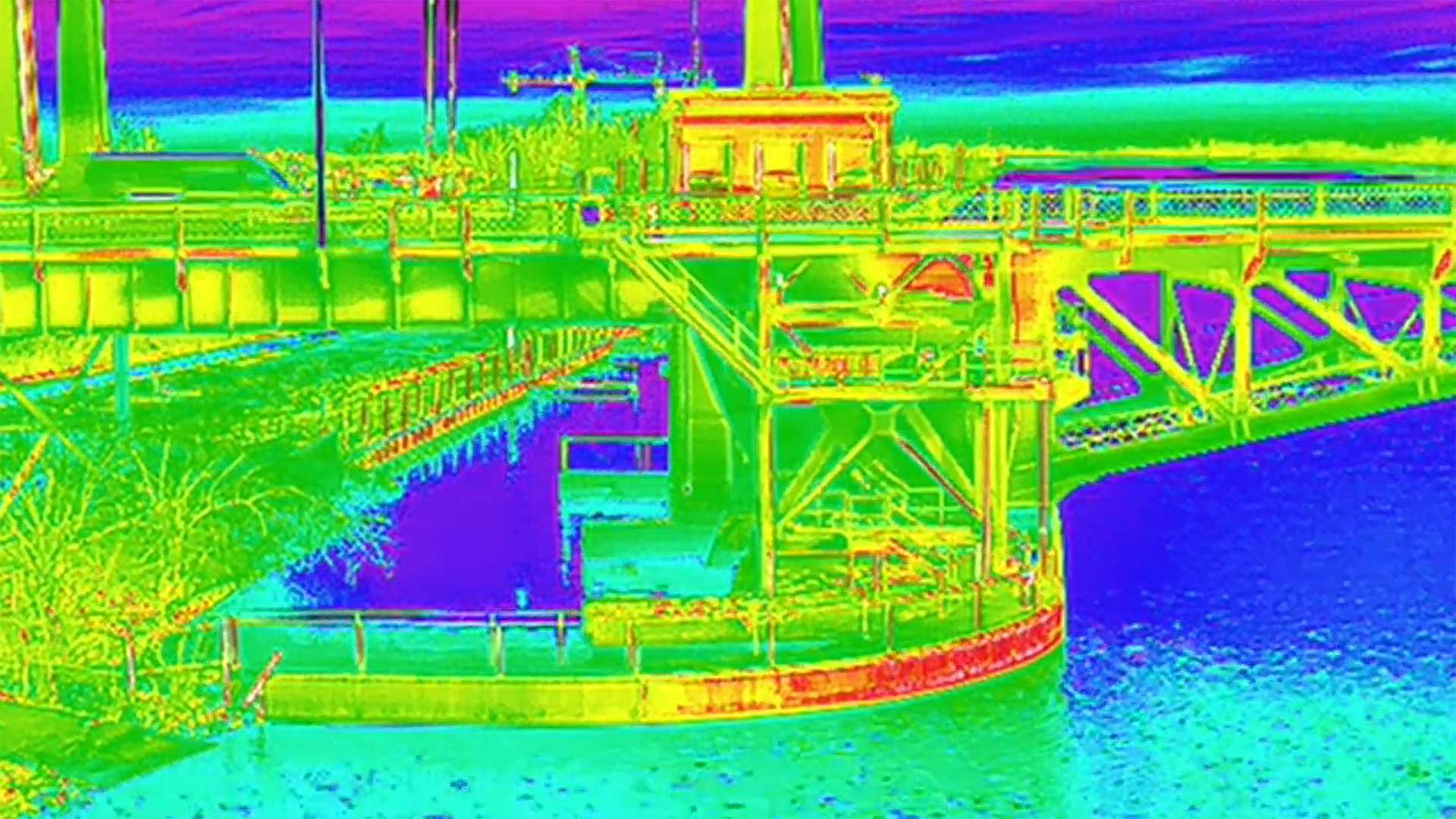

Thermal Imaging

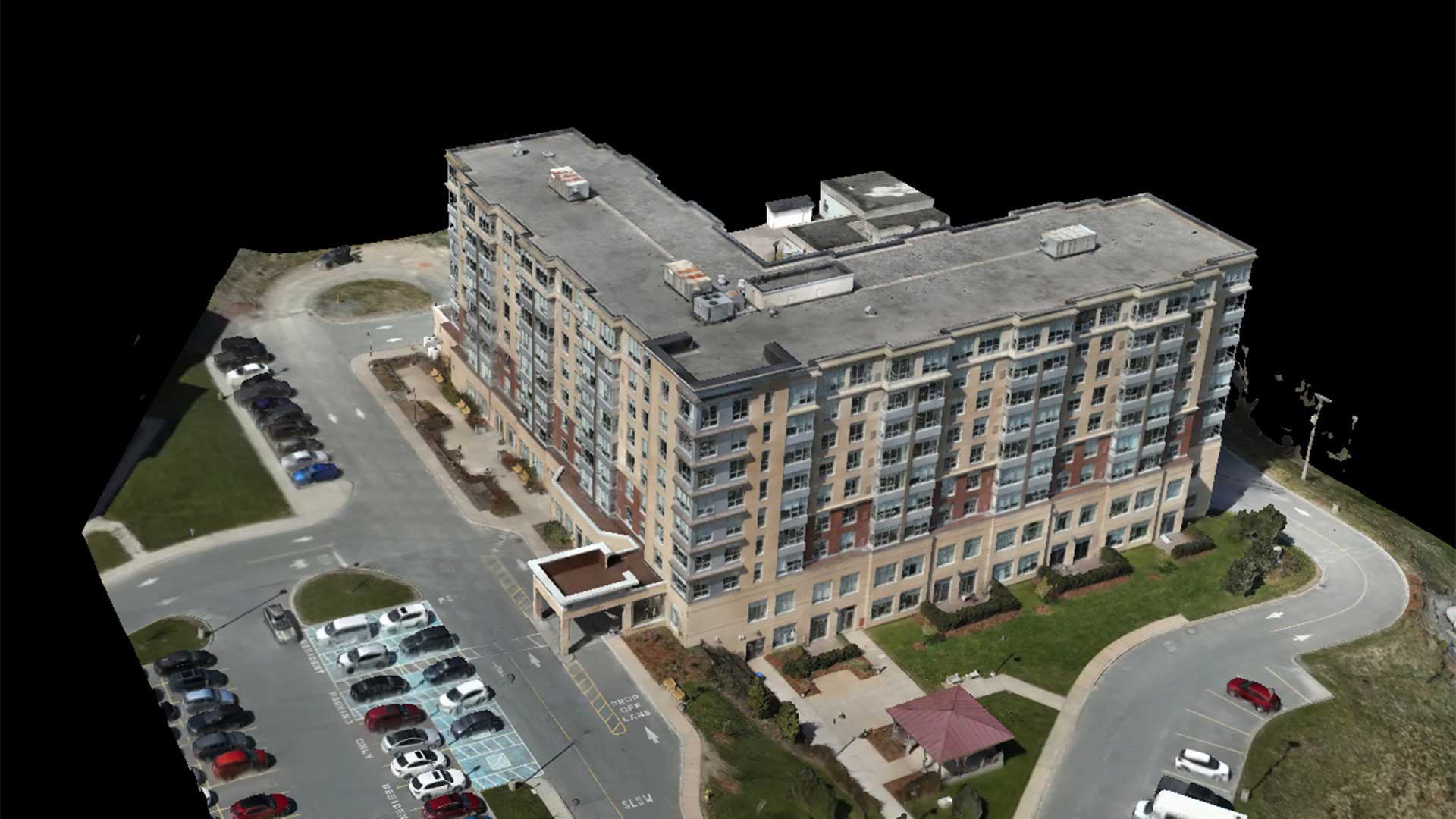

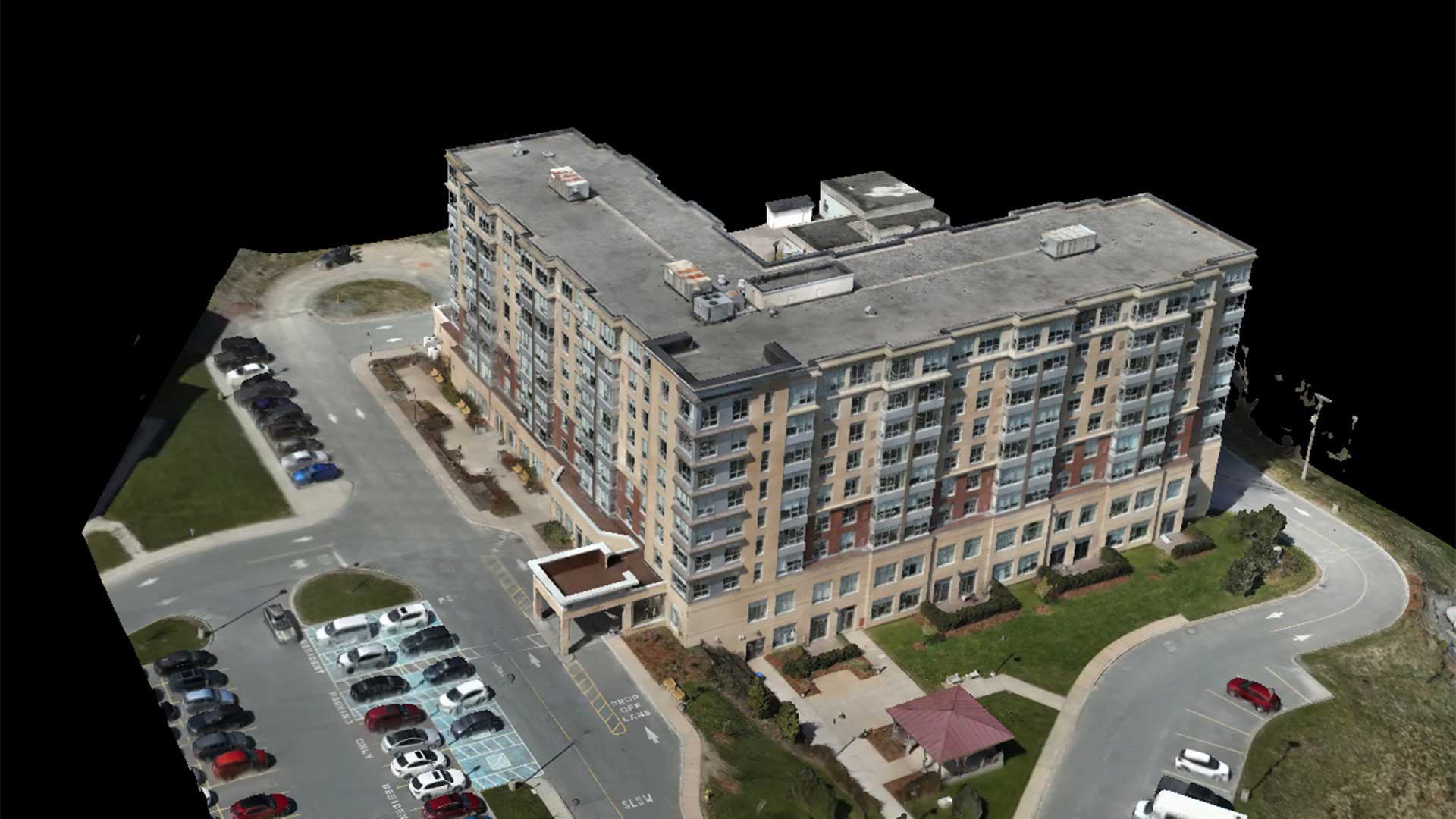

Photogrammetry

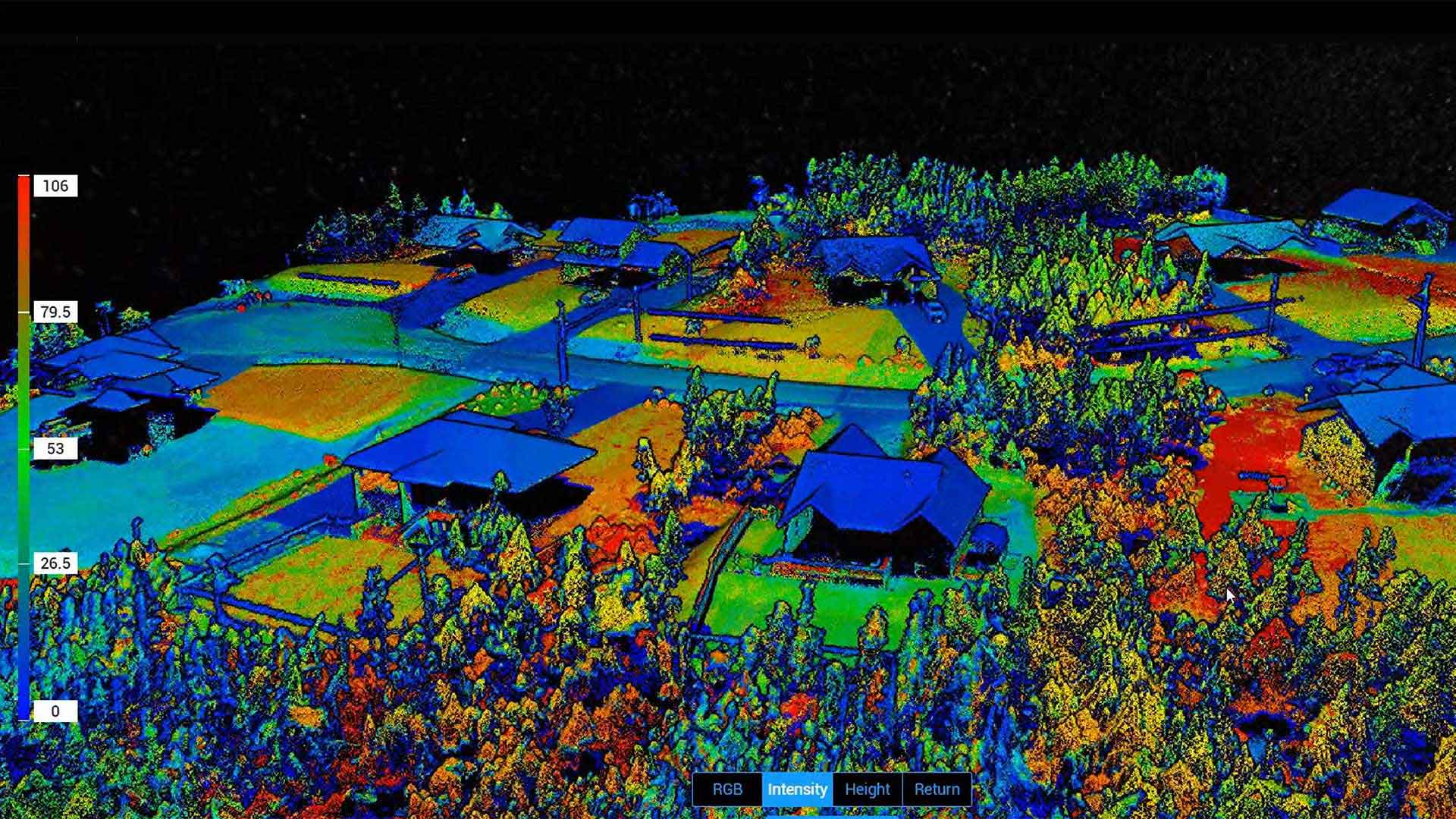

LiDAR

Ground Penetrating Radar

Fugitive Emissions Management

Drone Radiometric Surveys

Confined Space Inspections

Bathymetry

Artificial Intelligence